Stamping processing stamped part surface treatment

- Focus on OEM metal manufacturing. 100% inspection before shipping. Good service and reasonable price.

Stamping processing stamped part surface treatment

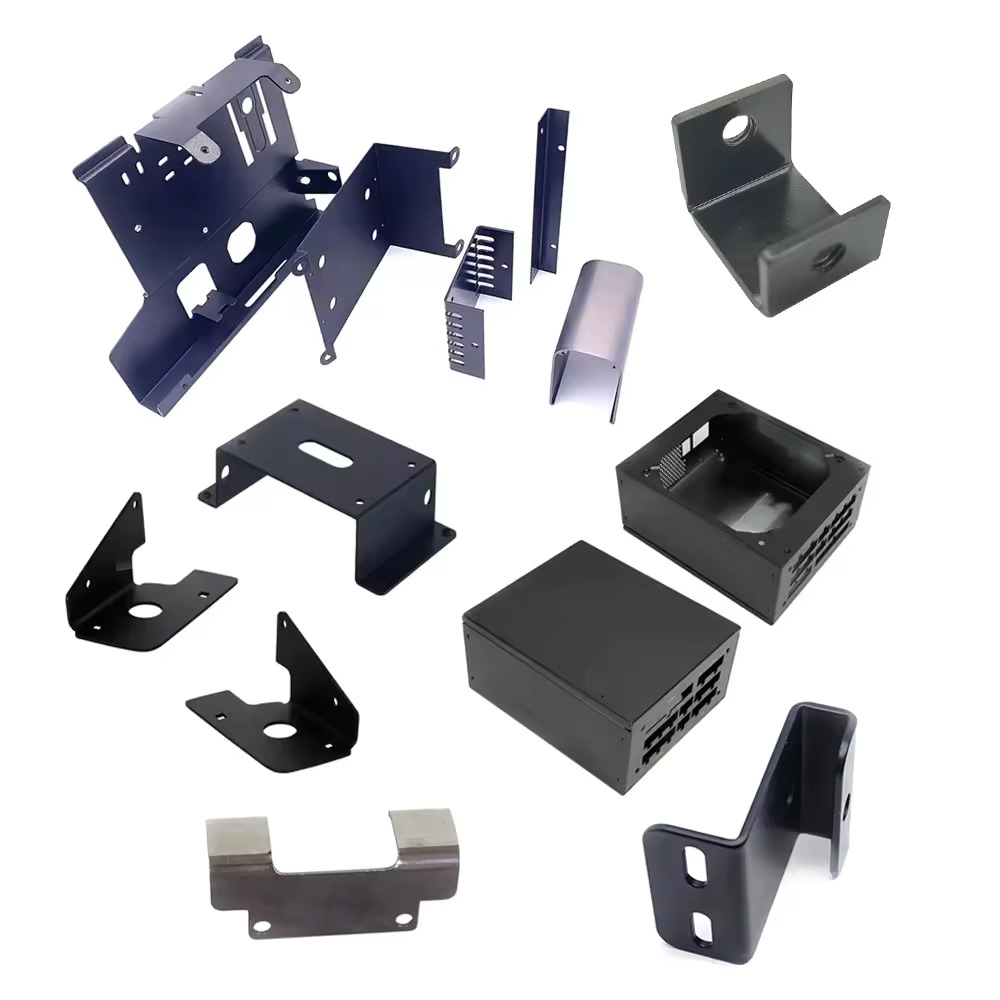

Product basic information:

Part name: Stamped part

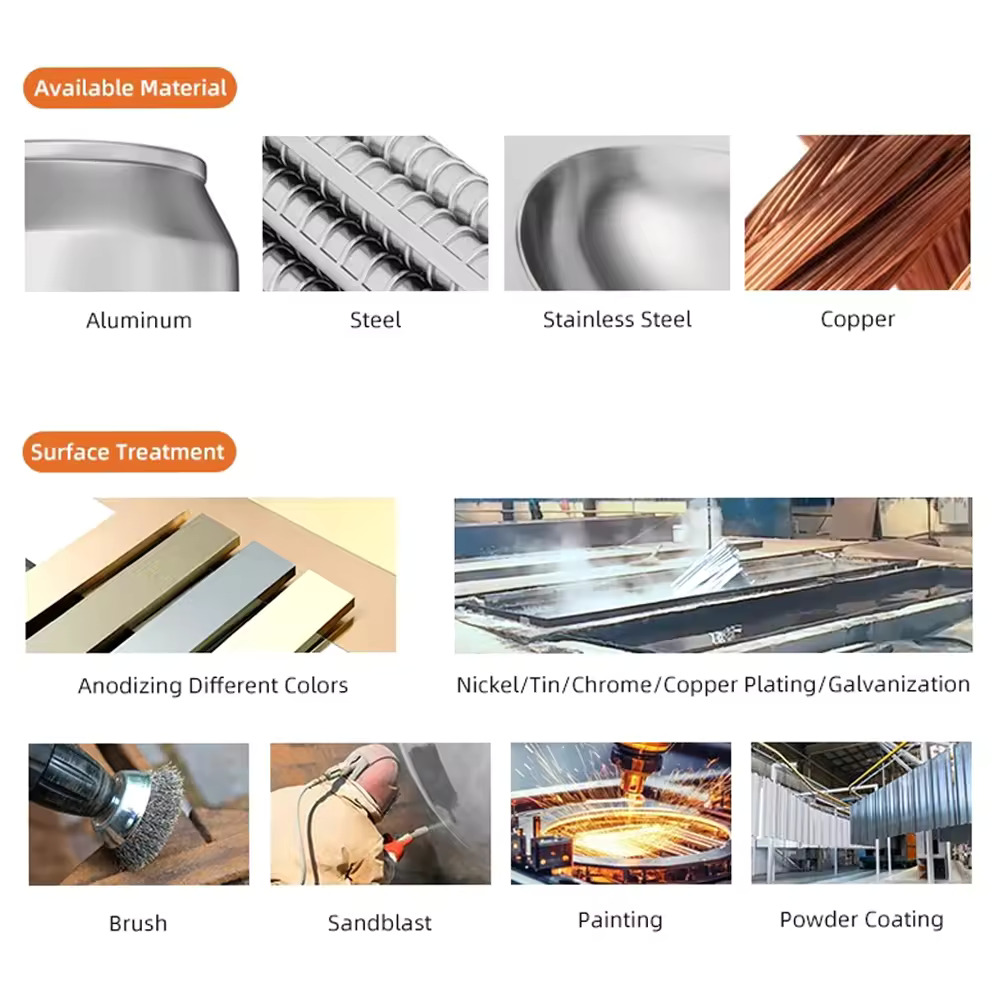

Part material: Aluminum/stainless steel/cold-steel/brass etc

Surface treatment: black powder coating/painting/sandblasting.

Delivery: 20-25 days.

QC control: 100% QC quality inspection before delivery.

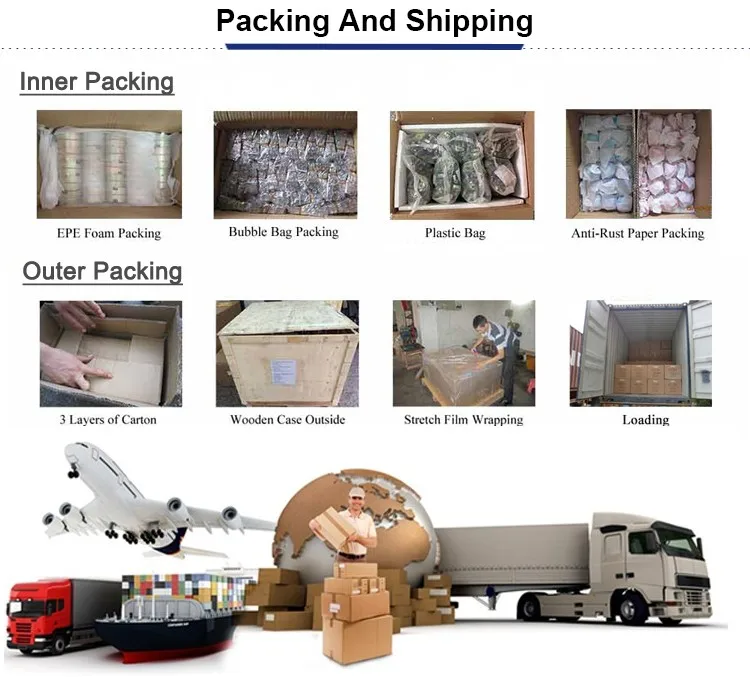

Packing: Netural packing or OEM as customer's request.

Product other information:

| Materials Available | Steel, Aluminum, Stainless Steel, SPCC/Iron, SGCC, etc |

| Processing | Laser Cutting, Bur Removing, Bending, Welding, Riveting, Printing, and Assembly |

| Surface Finish | Powder Coating, Sandblasting, Anodizing, Cleaning, Degreasing, Plating, etc |

| Thickness | 0.5-3mm |

| Quality Control | 100% Inspection before shipping |

| OEM Drawing Format | Auto CAD (IGS,STP,STL,and X-T), DWG,PDF,Pro-E, Solidworks,etc |

| Testing | At least 72 hours salt spray test; Thickness of plating or coating |

r

FAQ:

1. Where can i get product and price information?Contact us.in order to quote you as soon as possible,we need the following information:

a) Detailed drawings(format:CAD/PDF/DWG/DXF/DXW/IGES/STEP etc.)

b) Material.

c) Quantity.

d) Surface treatment.

e) Any special package or other requirements.

2.How can I get metal sample?

Yes, just need sample cost, we will return it back in mass production.

We also provide free samples in special conditions.

3.How about the lead time?

It depends on quantity, generally 7-15 days after order confirmation.

4.I want to keep our design in secret, can we sign NDA?

Sure, we will not display any customers' design or show to other people, we can sign NDA.

5.Can we know the production process without visiting the factory?

We will offer a detailed production schedule and send pictures and videos which show the machining progress.